Case Studies

Home / Case Studies / Edgewood College

Colorado State University, Pueblo

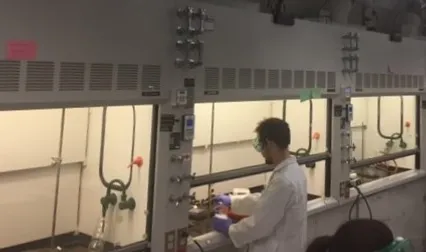

Fixed operational and safety issues in the laboratory airflow systems.

The Chemistry and Life Science Building airflow systems were energy inefficient and becoming less safe: 15 out of 34 fume hoods failed the certification test. This older equipment also lacked basic containment alarms.

In addition to safety concerns, the lab spaces were loud, uncomfortable, and very expensive to operate.

Turnkey retrofit of 39 Chemical Fume Hoods with new VAV controls and Auto Sashes.

Converted 3 Labs from CAV to VAV.

Installation included:

- Converted VAV controls to CAV fume hoods

- Replaced existing VAV fume hood controls, mono-blade dampers, & room pressure controllersReplaced fast acting exhaust valve actuators,

- Installed new fresh air bleed dampers and controllers Installed Automatic Sash closers

- Sealed lab room envelope to improve pressure cor

- Re-balanced the exhaust fans and static pressure control to decrease the noise level

- Certified fume hood safety & energy efficiency

"Our campus customers welcome the fume hoods upgrade. We appreciate how well your team provided service while delivering on-time and on-budget”

ESCO Engineering Manager*

* Reference available upon request

Summary

Industry: Higher Education

Location: Pueblo, CO

Annual Savings: $66,403

Simple Payback: 6.4 years

Energy Savings:

379,498 kWh/yr

59,277 Therms/yr